Specifications

General Specifications

| Specification | acA3800-10gm |

|---|---|

Resolution | 3840 x 2748 |

Sensor Type | ON Semiconductor MT9J003 Progressive scan CMOS Rolling shutter |

Optical Size | 1/2.3" |

Effective Sensor Diagonal | 7.9 mm |

Pixel Size (H x V) | 1.67 μm x 1.67μm |

Frame Rate | 10 fps |

Product Line | |

Mono / Color | Mono |

Image Data Interface | Fast Ethernet (100 Mbit/s) Gigabit Ethernet (1000 Mbit/s) |

Pixel Formats | See Pixel Format. |

Synchronization | Via hardware trigger Via software trigger Via free run |

Exposure Time Control | Programmable via the camera API |

Camera Power Requirements | Power over Ethernet (PoE) 802.3af compliant supplied via Ethernet connector 12–24 VDC supplied via I/O connector |

≈3.7 W when using Power over Ethernet ≈3.3 W @ 12–24 VDC when supplied via I/O connector | |

I/O Lines | |

Lens Mount | C-mount |

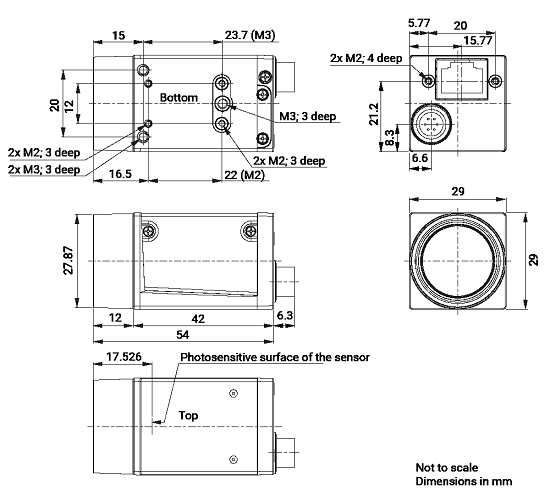

Size (L x W x H) | 42.0 mm x 29 mm x 29 mm (without lens mount or connectors) 60.3 mm x 29 mm x 29 mm (with lens mount and connectors) |

Weight | <90 g |

Conformity | CE (includes RoHS), UL Listed, FCC, GenICam, GigE Vision, IP30, IEEE 802.3af (PoE), REACH The EU Declaration of Conformity is available on the Basler website |

Software | Basler pylon Camera Software Suite (version 4.0 or higher) Available for Windows, Linux x86, Linux ARM, and OS X |

Accessories |

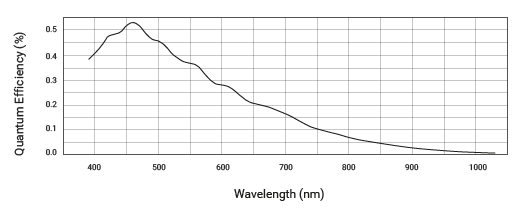

Spectral Response

The spectral response curve excludes lens characteristics and light source characteristics.

Mechanical Specifications

Camera Dimensions and Mounting Points

Maximum Allowed Lens Intrusion

→ See Maximum Allowed Lens Intrusion.

Stress Test Results

→ See Stress Test Results.

Requirements

Environmental Requirements

Temperature and Humidity

| Housing temperature during operation | 0–50 °C (32–122 °F) |

| Humidity during operation | 20–80 %, relative, non-condensing |

| Storage temperature | -20–80 °C (-4–176 °F) |

| Storage humidity | 20–80 %, relative, non-condensing |

| Housing temperature according to UL 60950-1 | max. 70 °C (158 °F) |

| Ambient temperature according to UL 60950-1 | max. 30 °C (86 °F) |

UL 60950-1 test conditions: no lens attached to camera; no heat dissipation measures; ambient temperature kept at 30 °C (86 °F). | |

Heat Dissipation

→ See Providing Heat Dissipation.

Electrical Requirements

DANGER

WARNING

NOTICE

Camera Power

Power supply via Power over Ethernet (PoE): Power must comply with the IEEE 802.3af specification.

Power supply via I/O connector: The operating voltage is 12–24 VDC. As a minimum, 10.8 VDC must be supplied. To avoid damaging the camera, a maximum of 30 VDC must not be exceeded.

Opto-Coupled I/O Input Line

| Voltage | Description |

|---|---|

30 VDC | Absolute maximum. This voltage must never be exceeded. Doing so may damage the camera and voids the warranty. |

0–24 VDC | Safe operating range. |

0–1.4 VDC | Indicates a logical 0 (with inverter disabled). |

>1.4–2.2 VDC | Region where the logic level transition occurs; the logical status is not defined in this region. |

>2.2 VDC | Indicates a logical 1 (with inverter disabled). |

| |

Opto-Coupled I/O Output Line

| Voltage | Description |

|---|---|

30 VDC | Absolute maximum. This voltage must never be exceeded. Doing so may damage the camera and voids the warranty. |

3.3–24 VDC | Safe operating range. |

<3.3 VDC | Unreliable I/O output. |

| |

Circuit Diagrams

→ See Circuit Diagrams for Basler ace Cameras.

Cable Requirements

Ethernet Cable

Use a high-quality Ethernet cable. Use of shielded CAT 5E or better cables with S/STP shielding is recommended.

Use either a straight-through (patch) or a cross-over Ethernet cable.

As a general rule, applications with longer cables or applications in harsh EMI conditions require higher category cables.

Close proximity to strong magnetic fields should be avoided.

Basler recommends using Ethernet cables from the Basler Vision Componentsrange.

I/O Cable

The I/O cable must be shielded.

The I/O cable must have a cross-section of at least 0.14 mm² (close to AWG26).

Use a twisted pair wire cable.

Maximum recommended cable length: 10 m

Camera-side connector: Hirose micro plug (part number HR10A-7P-6S) or equivalent

Close proximity to strong magnetic fields should be avoided.

If you are supplying power to the camera via Power over Ethernet, the I/O cable will not be used for power supply. However, you can still use the cable to connect to the I/O lines.

Basler recommends using I/O cables from the Basler Vision Components range:

Opto-I/O cable, 10 m (blue cable): For use with the opto-coupled I/O lines of your camera. Does not provide camera power. Therefore, when using this cable, you must provide power via Power over Ethernet (PoE).

Power-I/O cable, 10 m (gray cable): For use with the opto-coupled I/O lines of your camera. Unlike the opto-I/O cable (blue cable, see above), this cable provides camera power.

Opto-GPIO Y-cable, 2 x 10 m (yellow-blue cable): Offers two separate wires. One can be used to connect the opto-coupled I/O lines of your camera. The other one can be used to provide camera power.

Power-I/O PLC+ cable, 10 m (gray cable): For use with the opto-coupled I/O lines of Basler cameras connected to a programmable logic controller (PLC). It adapts the signal level for zero voltage from PLC level (<8.4 VDC) to TTL level (<1.4 VDC).

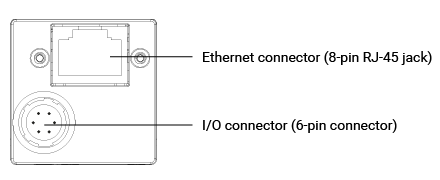

Physical Interface

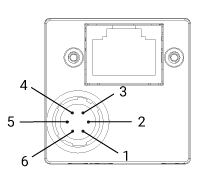

Camera Connectors

| Connector | Description |

|---|---|

| Ethernet connector |

|

| I/O Connector |

|

Connector Pin Numbering and Assignments

| Pin | Line | Function |

|---|---|---|

| 1 | - | 12–24 VDC Camera Power |

| 2 | Line 1 | Opto-coupled I/O input line |

| 3 | - | Not connected |

| 4 | Out 1 | Opto-coupled I/O output line |

| 5 | - | Ground for opto-coupled I/O lines |

| 6 | - | Ground for camera powe |